The Agimix Intensive Disperser Mixer is designed to ensure excellent homogenization in industrial processes involving high solid content. Its advanced technology guarantees efficiency and quality in material mixing, meeting the specific demands of various industrial sectors.

Know some common applications for Intensive Agimix Dispersers.

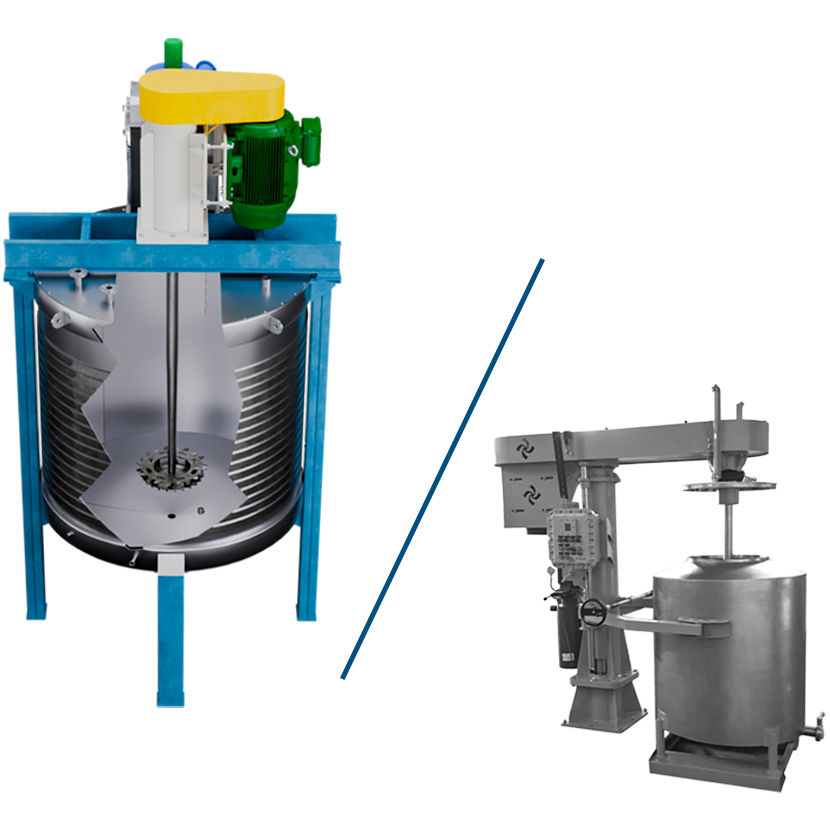

Discover the main differences between the Agimix Intensive Disperser and the Hydraulic Lift Disperser.

| Feature | Intensive Disperser | Hydraulic Lift Disperser |

|---|---|---|

| Application type | High viscosity and solids | Processes with varying levels |

| Mixing efficiency | High | Moderate |

| Operational complexity | Low | High |

| Operational cost | Moderate | High |

| Maintenance | Simple | Complex |

See some frequent doubts that can answer your questions about the Agimix Intensive Disperser Mixer .

An intensive disperser is equipment that applies high shear forces to mix, disperse solids into liquids, break down agglomerates, emulsify immiscible phases, and more. It typically features a rotor or impeller (sometimes a rotor-stator) that rotates at high speed within a fluid, creating turbulence, vortices, and flows that efficiently disperse particles.

Some factors to consider:

Some recommended practices:

It depends greatly on the application:

Yes — some recommended practices:

This depends on several factors, such as:

Frequently, initial test batches are performed to determine the ideal time for a specific formulation.

Yes, but with some adaptations: