Hydraulic spine dispersers guarantee excellent agility in batch production.

Discover the key advantages of the Agimix Hydraulic Lift Disperser and understand why it is the ideal choice to enhance the efficiency and safety of your industrial process.

It allows to regulate the height of the disperser set according to the volume and viscosity of the product, ensuring greater process efficiency.

Homogeneous and fast mixture, reducing production time and improving the final quality of the product.

Ideal for paint, varnishes, cosmetics, food, chemicals and pigments industries.

Robust hydraulic system reduces physical effort, minimizes risks and meets safety standards (NR-12).

The lift system facilitates access to discs and axes, making cleaning and maintenance faster.

Built with high quality materials, it offers long service life and reduces stops and repairs.

More yield, lower waste and optimization of the industrial process, increasing the return on investment.

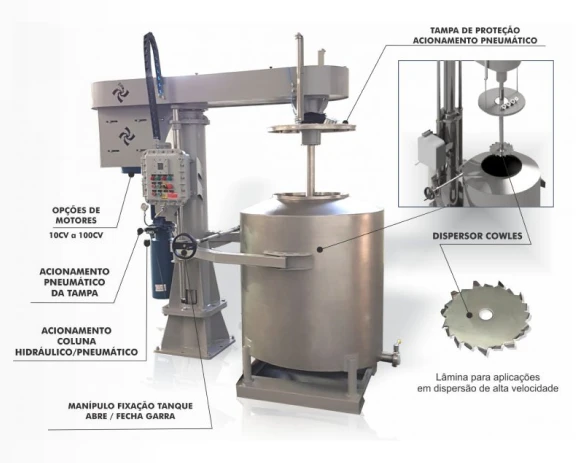

Possibility of adapting to different capacities, powers, disk types and building materials as the customer's needs.

In this section, we have gathered the main questions about the Agimix Hydraulic Lift Disperser so you can better understand how the equipment works, its advantages, and how it can increase the productivity of your industrial process.

A hydraulic lift disperser is a fluid agitation/dispersing equipment (liquids, suspensions, emulsions) that features a hydraulic system allowing the dispersion assembly (shaft, disc/impeller, motor) to be raised and lowered in a controlled manner. This facilitates:

It is widely used in paint, varnish, chemical, cosmetic, additive, food, pigment industries, etc.

Some examples:

| Criterion | Importance |

|---|---|

| Material viscosity | The more viscous, the more power is needed, a larger or more suitable disc, and immersion height control is crucial. |

| Production volume | For large batches, a disperser with a shaft/impeller sized for that volume is required. |

| Rotation speed / shear rate | Dispersion depends heavily on this; materials with fine particles or solids require high rotation and a suitable disc. |

| Construction material | For resistance to corrosion, abrasiveness, or if used for food/cosmetics. Stainless steel, polished finishes, etc. |

| Hydraulic system | Check lift stroke, hydraulic force, and ease of maintenance of the system. |

| Available space | Total height with disperser lowered/raised, access for operation and maintenance. |

Yes. The Agimix Hydraulic Lift Disperser is designed for continuous operation, with high-durability components and a robust hydraulic system, ensuring stability and performance even during long work shifts.

To ensure maximum safety and efficiency, it is recommended to follow the manual instructions, perform preventive maintenance, monitor the motor and hydraulic system temperature, and keep lubrication and periodic inspections up to date. This way, your equipment operates reliably and at high performance throughout the entire production process.