O que é e quais as aplicações do Ribbon Blender

Se você quer saber o que é e quais as aplicações do Ribbon Blender, entenda que na Agimix você encontra modelos nas versões standards que estão disponíveis em capacidades de 50 a 10.000 litros úteis, com diversos opcionais.

O que é

Ribbon Blender?

The Ribbon Blender is an industrial mixer designed to homogenize quickly and evenly dry materials, granules, and even liquid mixtures. Its name comes from the blades shaped like a ribbon (or “ribbon”), arranged in a U-shaped trough, which rotate in opposite directions to move the product in all directions, ensuring an efficient mix.

Widely used in the food, chemical, pharmaceutical, cosmetic, and agricultural industries, the Ribbon Blender stands out for its versatility, low energy consumption, and capacity to process large volumes in a short time. It is the ideal solution for those seeking production standardization, increased productivity, and easy cleaning between batches.

Aplicações

do Ribbon Blender

The Ribbon Blender is used to mix various ingredients efficiently and uniformly, ensuring consistency and quality in the final product. It is ideal for industries that require fast, precise and versatile mixing, whether with dry materials, granules, or liquid mixtures.

Main Applications of the Ribbon Blender

Food Industry: mixing flours, seasonings, coffee, powdered milk, animal feed, and other dry ingredients.

Pharmaceutical Industry: homogenization of medications, vitamins, supplements, and excipients, ensuring consistency and batch quality.

Chemical Industry: mixing pigments, resins, fertilizers, pesticides, and powdered soaps with high precision.

Cosmetics and Plastics: production of creams, lotions, polymers, and additives, maintaining ingredient integrity.

Other Sectors: minerals, metals, paints, and mortars, where uniform mixing is essential for quality and standardization.

The Ribbon Blender is, therefore, a versatile equipment that serves different industrial sectors, being indispensable for those seeking productivity, efficiency, and consistent results in material mixing.

Funcionamento

e características

The Ribbon Blender is used for efficiently mixing materials, ensuring homogeneity and uniformity in every batch. Its operation is based on ribbon-shaped blades that rotate inside a “U”-shaped trough, promoting a continuous movement of the product both in the radial direction and the axial direction.

The main use of the Ribbon Blender includes:

Uniform mixing of powders and granules: the ribbon blades move the material from the inside out and from the outside in, ensuring homogeneity in a short time.

Processing of large volumes: the design allows mixing large quantities quickly and efficiently, without compromising quality.

Mixing of solids with liquids: some models allow adding liquids during the process without compromising uniformity.

Continuous and safe operation: with a reliable gearmotor and discharge valve, the equipment allows quick discharge and easy cleaning.

Industrial versatility: it is commonly used in food, chemical, pharmaceutical, cosmetic, and agricultural industries, adapting to different ingredients and production volumes.

The Ribbon Blender, therefore, not only mixes materials, but also ensures efficiency, productivity, and standardization, being an essential equipment for industrial processes that require quality and consistency.

Misturadores tipo Ribbon Blender Agimix

são ideais para mistura de materiais sólidos

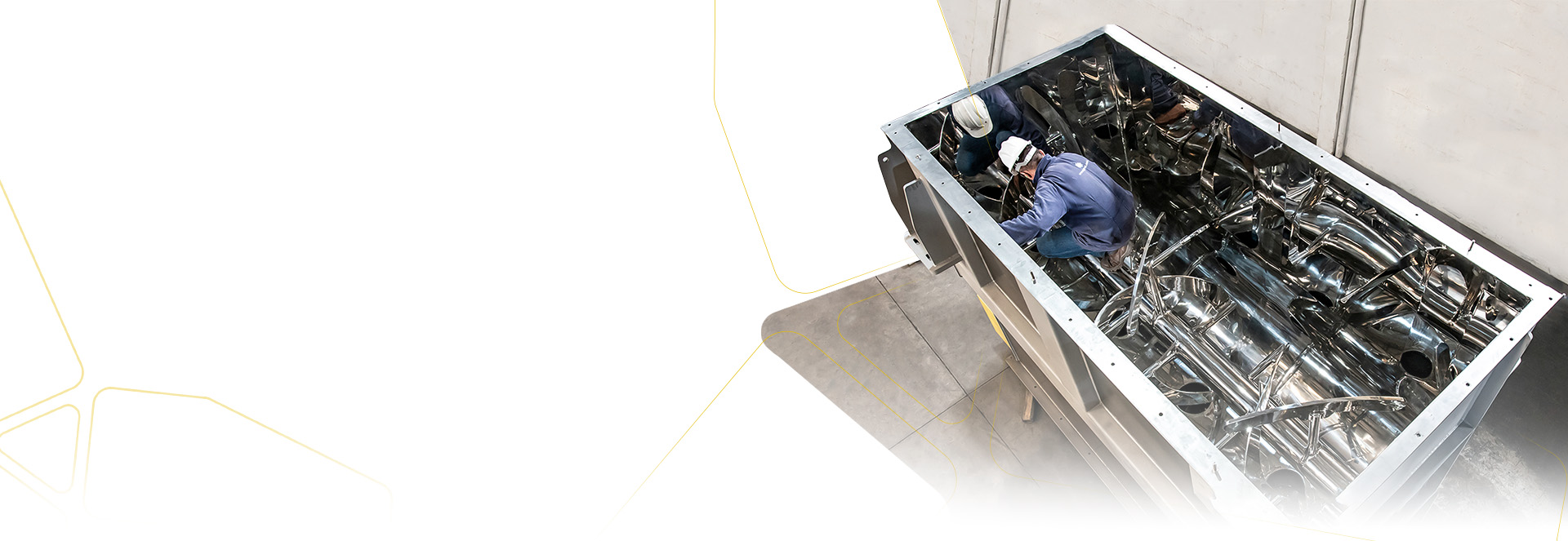

The Agimix Ribbon Blender mixers are ideal for mixing solid materials or with low moisture content, offering high efficiency and excellent homogenization. They can be built with ribbon blades or “paddle” arms, ensuring uniform mixing in different industrial applications.

These mixers achieve homogeneity levels with deviations of less than 3%, in mixing times ranging from 3 to 10 minutes. In addition, they feature a safety system with door locking and emergency stop button, following the guidelines of NR-10 and NR-12 standards.

The Agimix Ribbon Blenders comply with all ANVISA regulations and resolutions for food and pharmaceutical processes, also following Good Manufacturing Practices (GMP), ensuring quality, safety, and reliability in production.

Advantages

From Ribbon Blender

Using the Ribbon Blender offers several advantages, such as:

- Uniform and efficient mixing:

Ensures the final product quality and minimizes waste.

- Low shear:

Preserves the integrity of sensitive materials, such as pharmaceutical and food products.

- Fast and complete discharge:

Minimizes product loss and optimizes process time.

- Modular design:

Allows customization according to client needs.

- Stainless steel construction:

Ensures high durability and corrosion resistance.

- Easy operation and maintenance:

Reduces operating costs and labor.

Como escolher o

Ribbon Blender ideal

Choosing the ideal Ribbon Blender is essential to ensure efficiency, homogeneity, and productivity in your industrial process. With Agimix, you get high-quality equipment, customized and with specialized technical support, ensuring the best purchase and operation experience.

1. Capacity and production volume

Define the Ribbon Blender capacity according to the volume of ingredients you need to process. Agimix Ribbon Blenders handle everything from small batches to large volumes, providing fast mixing and maximum efficiency.

2. Type of material to be mixed

Check if the Ribbon Blender is suitable for the type of ingredients in your production: dry powders, granules, wet mixes, or sensitive ingredients. Agimix offers models in 304/316 stainless steel or carbon steel, ensuring durability and compatibility with your product.

3. Additional functions and customizations

Agimix Ribbon Blenders can include heating, cooling, thermal insulation, quick discharge valve, or liquid addition, increasing versatility and industrial process efficiency.

4. Safety and certifications

Agimix ensures all equipment meets safety standards (NR‑10, NR‑12) and, when necessary, Good Manufacturing Practices and ANVISA guidelines, guaranteeing reliability and protection for your team.

5. How to buy the Ribbon Blender with Agimix

When deciding how to buy, rely on Agimix, a reliable and specialized supplier:

- Request a custom quote based on capacity, material, and extra functions.

- Receive specialized technical support and maintenance.

- Ensure easy operation, cleaning, and durability of the equipment.

- Have the peace of mind of investing in a Ribbon Blender that delivers superior performance from the first use.

With Agimix, you ensure your Ribbon Blender is ideal for your process, providing homogeneous mixing, maximum productivity, and guaranteed efficiency.

Fale com a Agimix

The Ribbon Blender is a versatile and efficient equipment for bulk solids mixing, used in various industries to ensure high-quality final products. Its main advantages include homogeneous and fast mixing, low shear, complete discharge, modular design, and stainless steel construction. Choosing the ideal Ribbon Blender should consider factors such as production volume, material characteristics, desired homogeneity level, and available space.

If you still have doubts about what it is and the applications of the Ribbon Blender, get in touch with the Agimix team now. Talk to Agimix by filling out the form below or clicking the WhatsApp button and discover how to ensure efficient mixing, productivity, and quality in your production.

Contact

Request your quote

*Required fields