How Does Viscosity Affect Mixture Performance?

Viscosity is one of the most critical fluid properties that affect the performance of an industrial agitator.

Understanding the Role of Viscosity in Mixing

In industrial processes, fluid mixing is essential to ensure quality and production control. It is crucial to understand and configure the mixer according to several factors — and one of the most important is viscosity. The physical properties of materials, especially viscosity, determine how efficient the agitation, homogenization, or dispersion process will be. Whether in food production, mining processes, water treatment, adhesive manufacturing, or the petrochemical industry, viscosity and its characteristics directly influence equipment design, energy consumption, impeller selection, flow pattern, and the final quality of the product or reaction.

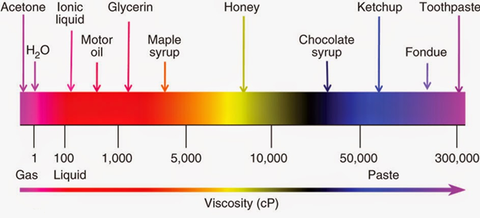

Viscosity is the resistance a fluid offers to flow or deformation. It defines how easily a substance moves when a force is applied. In mixing processes, the higher the viscosity, the greater the energy required to move the material, making the flow more difficult. In short, viscosity can either enhance or hinder mixing performance — it all depends on how well it is understood and accounted for in the mixer design.

What Is Viscosity and How It Is Measured

Viscosity is generally divided into two types: dynamic (or absolute) viscosity and kinematic viscosity.

Dynamic viscosity, measured in centipoise (cP), indicates the internal resistance of a fluid to flow when subjected to a force. This is the most common type of viscosity in mixer applications — and usually the starting point in performance analyses.

Meanwhile, kinematic viscosity takes the fluid’s density into account and is expressed in centistokes (cSt).

In industries, viscosity is determined using viscometers or rheometers, available in various designs and technologies. Many of these instruments are developed for specific sectors — which makes sense, since different processes require different levels of precision.

In short: viscometers are ideal for Newtonian fluids — whose viscosity remains constant regardless of the shear rate —, while rheometers are essential for non-Newtonian fluids, whose viscosity changes according to the applied force.

Common Tools for Measuring Viscosity

Viscosity plays a fundamental role in fluid dynamics and mixing system performance. Although early measurement methods date back to the 19th century — using simple capillary tubes — modern technology has introduced a wide range of tools designed for more accurate and specific measurements.

Below are some of the most commonly used methods across various industrial sectors:

1. Capillary Viscometers

This classic method measures the time required for a liquid to flow through a narrow capillary tube under the influence of gravity. Known as Ostwald or Ubbelohde viscometers, they are still widely used due to their simplicity and precision, especially for low-viscosity fluids.

2. Zahn Cups

Widely used in the paint and coatings industry, Zahn cups are handheld tools with a small orifice at the bottom. Viscosity is determined by the time it takes for the liquid to flow out of the cup. Although not highly precise, they are valued for providing quick and comparative measurements directly on the production floor.

3. Falling Ball or Piston Viscometers

These devices measure the time it takes for a ball or piston of known density to fall through a fluid. The resulting data allows for viscosity calculation, making it a practical option for contexts such as marine fuel testing, where fast results are required.

Piston-based versions follow the same principle and are ideal for field applications due to their durability and ease of use.

4. Vibrational Viscometers

In this method, an oscillating sensor is immersed in the fluid and measures resistance to vibration, which is directly related to viscosity. They are ideal for continuous or inline monitoring in both batch and continuous processes, ensuring real-time product uniformity.

5. Rotational Viscometers

Among the most versatile and popular methods, rotational viscometers measure viscosity based on the torque required to rotate a spindle within the fluid. They are widely used in quality control across various industries.

Some models allow continuous monitoring during processing, providing valuable trend data. However, torque systems can be mechanically complex and require periodic maintenance due to the use of slip rings or other transmission components.

6. Resonant and Wireless Viscosity Sensors

The latest generation of sensors uses wireless torque transmitters and resonant frequency technology. These systems eliminate physical connections to rotating shafts, transmitting power and data through radio frequency (RF) signals.

With no moving parts, they offer high resistance to vibration and can operate over wide temperature ranges, making them ideal for demanding industrial environments. Furthermore, their plug-and-play design minimizes the need for user calibration.

Leave the technical aspects of your project to Agimix and get a project tailored to your production needs.

How Viscosity Influences Mixing Dynamics

Mixing high-viscosity fluids presents specific engineering challenges. The thicker the substance, the greater its resistance to flow and agitation. Below are the main ways viscosity affects mixing performance:

1. Required Power and Torque

As viscosity increases, so does the amount of energy required to agitate the fluid. Denser materials demand mixers with higher torque and reinforced drive systems. This is one of the first factors to consider in the design of an industrial mixer.

2. Flow Patterns

The type of flow is one of the key aspects of the mixing process.

- Low-viscosity fluids allow for turbulent flow, which enhances homogenization through shear and convection currents while requiring less energy.

- High-viscosity fluids, on the other hand, tend to exhibit laminar flow, which reduces mixing zones and demands different strategies to achieve uniform mixing.

3. Impeller Efficiency

The type and speed of the impeller directly influence performance when dealing with viscous materials.

Axial-flow impellers work well with low-viscosity liquids, while radial or helical ribbon-type impellers are more suitable for thick, hard-to-move mixtures.

4. Heat Transfer

In high-viscosity systems, the heat generated during mixing may not dissipate efficiently, which can affect product stability, especially in processes involving temperature-sensitive materials.

5. Mixing Time

More viscous fluids generally require longer times to reach the desired homogenization. Therefore, engineers must balance process efficiency with production demands, often relying on innovative equipment designs to optimize performance.

How Customization Improves Mixing Results

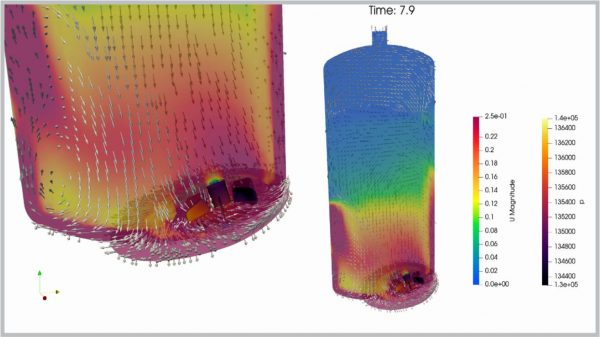

Standard mixers rarely meet the specific requirements of high-viscosity fluids. A truly optimized mixing design considers the unique characteristics of each process, including tank geometry, batch size, shear sensitivity, and temperature control.

First, the mechanical design is analyzed. Then, the operational process. And finally, the application environment — often the most critical factor, and the reason why Agimix maintains its technical and customized approach to every project.

Agimix has built its reputation by developing tailor-made mixing systems, designed to meet the exact needs of each customer. Using application data and viscosity profiles, the company defines the types of impellers, drive systems, and mounting configurations that optimize mixing efficiency — without oversizing the equipment.

Customization also contributes to energy efficiency, preventing common mistakes such as oversized motors or underestimation of the required torque. Each mixer is engineered for durability, performance, and ease of maintenance.

How to Solve Mixing Problems Related to Viscosity

Issues arising from incompatibility between fluid viscosity and mixer design may include:

- Inconsistent product quality: poor ingredient distribution can cause excess or lack of concentration in certain areas.

- Excessive wear and maintenance: mixers with insufficient power in high-viscosity environments can suffer accelerated wear.

- Excessive heating: inefficient heat dissipation in viscous media can compromise temperature-sensitive ingredients.

Regularly reviewing process parameters and monitoring viscosity variations caused by temperature, composition, or shear can prevent operational failures.

Agimix provides on-site evaluations and technical support, ensuring operational consistency and long-term performance.

Need a customized project that fits your production process perfectly? Contact Agimix and get a free quote.

Final Considerations: Viscosity Is the Variable That Truly Matters

| Consideration | Description |

|---|---|

| Data Logging | Enables real-time viscosity monitoring for better process control |

| Scalability | Lab testing should reflect full-scale mixing challenges |

| Material Compatibility | Mixer materials must resist corrosion or abrasion from viscous substances |

| Automation Integration | PLC integration helps control speed, torque, and mixing duration |

While many factors influence the success of a mixing process, few are as critical and impactful as viscosity. Understanding its role, measuring it accurately, and designing solutions adapted to its limitations are what ensure superior and consistent results.

Agimix maintains a continuous commitment to innovation and customer-focused engineering.

Our mixers are not just equipment — they are tailor-made solutions, shaped by viscosity, performance goals, and our customers’ trust.

Learn more about how Agimix designs and customizes its mixing systems to deliver efficiency, reliability, and high-performance results.

Are you interested?

Request your quote

*Required fields