AGIMIX industrial agitators are developed with advanced engineering to maximize process efficiency, reducing energy consumption and ensuring high operational performance.

Watch the video next to it and check out the operation of the equipment.

Versatility and Applications

The Agimix industrial vertical agitators are used in various sectors, including:

Efficiency and Customization

The industrial vertical agitator is used in a wide range of fluid-handling processes. Our agitators are built in various sizes to meet the specific needs of each sector. We offer industrial agitators suitable for:

Benefits of Agimix Industrial Agitators

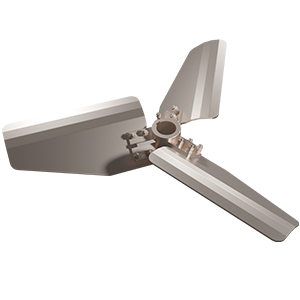

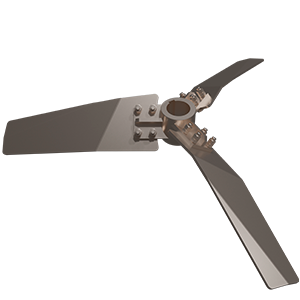

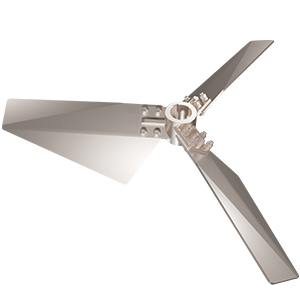

| AGX-AE339 | AGX-HY339 | AGX-HYS345 | AGX-PBT445 | |

|---|---|---|---|---|

| Image |  |

|

|

|

| Regime | Turbulent | Turbulent | Turbulent | Turbulent / Transitional |

| Viscosity | <5,000 cPs | <5,000 cPs | <10,000 cPs | <25,000 cPs |

| Operations | Miscible Mixing Heat Exchange Fine Solids Suspension Solids Dissolution |

Miscible Mixing Heat Exchange Fine Solids Suspension Solids Dissolution |

Miscible Mixing Heat Exchange Fine Solids Suspension Solids Dissolution |

Miscible Mixing Heat Exchange General Use |

| Flow | Axial | Axial | Axial | Axial |

| Power | Low | Low | Medium | Extreme |

| Pumping | Low | Low | Medium | High |

*Information may change without prior notice. Please consult Agimix.

The Agimix Vertical Industrial Agitator is equipment designed to perform mixing, homogenization, dispersion, and suspension maintenance of liquids and pastes in industrial tanks.

With national engineering and custom manufacturing, it is widely used in the sugar-energy sector (ethanol, sugar, fermentation, and juice treatment), as well as in chemical, food, pharmaceutical, cosmetic, and environmental industries.

Its vertical design ensures continuous and homogeneous mixing, reducing processing time and energy consumption while ensuring uniformity and stability of the final product.

The equipment is highly versatile and serves a wide range of industrial sectors.

The main segments served are:

Agimix agitators are designed to withstand aggressive environments, with high solid content and temperature variations, typical in sugar and ethanol plants.

Choosing an Agimix Vertical Agitator means opting for a solution engineered with precision design, full customization, and focus on continuous performance.

More than just equipment, it is the result of decades of experience in the development of industrial mixing technologies that combine energy efficiency, durability, and operational reliability.

Each agitator is custom-designed, taking into account the viscosity, density, temperature, and rheological behavior of the fluid — ensuring that the agitation system delivers homogeneous mixing, efficient dispersion, and process stability, regardless of the application sector.

At Agimix, every project goes beyond the standard. The vertical agitator is analyzed, calculated, and optimized for the customer’s tank and product, balancing speed, torque, impeller type, and flow geometry to achieve maximum production efficiency with minimum energy consumption.

With a reinforced structure, dynamically balanced shafts, high-durability bearings, and reliable sealing, the Agimix vertical agitator is built to operate in demanding industrial environments such as those found in the sugar-energy sector, where robustness and process consistency are essential.

Companies in the sugar, ethanol, food, chemical, and wastewater industries trust Agimix agitators for their mechanical longevity, ease of maintenance, and proven field performance. Each model is designed to minimize downtime, prevent failures, and maintain consistent final product quality over time.

Beyond equipment engineering, Agimix offers specialized technical consulting, assisting clients from sizing to installation and operation. This ensures not just an agitator, but a complete industrial mixing and agitation solution — ready to boost productivity, optimize resources, and deliver sustainable and consistent results.

With Agimix, you have safety, performance, and national technical support in equipment that transforms your production process into a competitive advantage.

The choice of the ideal impeller is not made generically: Agimix determines the best model based on technical studies and CFD (Computational Fluid Dynamics) simulations, ensuring maximum agitator performance for each application.

The process considers:

Based on this data, Agimix defines:

As a result, each Agimix agitator is fully optimized for the customer’s process, providing higher productivity, durability, and reliability, especially in demanding sectors such as sugar-energy, chemical, food, and environmental industries.

Yes! The Agimix Vertical Agitator was designed to maximize energy efficiency and reduce operational costs without compromising performance or durability.

Some factors that ensure its efficiency:

Combining custom engineering, cutting-edge technology, and intelligent operation, the Agimix Vertical Agitator delivers high productivity with lower energy consumption, making it an economical and reliable solution for the chemical, food, sugar-energy, and environmental industries.

Yes! All Agimix vertical agitators are custom-designed to meet the specific needs of each industrial process. Customization goes far beyond tank size or motor power — it considers product characteristics, process objectives, and operating conditions.

Some of the main aspects that can be customized include:

With this approach, Agimix delivers fully customized solutions, ensuring energy efficiency, greater durability, and consistent results, especially in critical processes of the sugar-energy, chemical, food, and environmental sectors.

Each agitator is, therefore, a unique engineering solution, developed to optimize your process and increase productivity, offering safety and reliability in all operations.

Yes! Agimix vertical agitators are designed to meet the highest standards of hygiene, safety, and quality, making them ideal for food, pharmaceutical, and beverage industries.

Main factors ensuring safety and compliance:

With this, the Agimix agitator delivers homogeneous mixing, maintenance of product integrity, and total safety, allowing food, beverages, and pharmaceuticals to be processed with quality, reliability, and regulatory compliance.

The maintenance of the Agimix vertical agitator is designed to be simple, safe, and efficient, ensuring longevity, continuous performance, and reduced unplanned downtime.

Main maintenance points:

With these measures, the Agimix vertical agitator maintains homogeneous mixing, operational safety, and high productivity, while reducing maintenance costs and extending equipment lifespan, even in demanding industrial processes such as sugar-energy, chemical, food, and pharmaceutical sectors.

The Agimix vertical agitator stands out for offering custom engineering, high durability, and maximum efficiency, features that go beyond generic equipment available in the market.

Main differentiators compared to competitors:

In summary, the Agimix vertical agitator combines customization, reliability, cost efficiency, and technical support in a single piece of equipment, delivering superior results in productivity, efficiency, and durability — features that place Agimix ahead in the industrial agitation market.