Ebonite Coating: How to Increase the Durability and Performance of Industrial Agitators?

This article explains what ebonite is, why the material is so used in industrial coatings, what benefits it brings to the agitation system and in which types of applications this coating is especially advantageous.

When we talk about increased durability, chemical resistance and operational safety in industrial mixers, ebonite lining emerges as one of the most efficient solutions available. Recently, Agimix developed a special project for an ebonite-lined agitator to meet a highly corrosive process. This project reinforces the company's commitment to delivering robust, efficient equipment prepared for the most challenging industrial environments.

This article explains what ebonite is, why the material is so widely used in industrial linings, what benefits it brings to the agitation system, and in which types of application this lining is especially advantageous.

What is Ebonite?

Ebonite, also known as vulcanized hard rubber, is a material obtained from an intense process of vulcanizing natural rubber with sulfur. This process generates a rigid and resistant polymer, capable of withstanding:

- strong chemical attack

- abrasion

- high mechanical stresses

- temperature variations

- humid and corrosive environments

Because of its resistance, ebonite is widely used to line industrial components with the aim of protecting metallic surfaces against corrosion and wear.

Why Use Ebonite in Industrial Agitators?

Industrial agitators operate in aggressive scenarios, often immersed in corrosive, abrasive, or highly acidic fluids. Without proper lining, components like the shaft, propeller, and flanges can suffer accelerated wear and loss of performance.

Ebonite stands out because it forms a barrier resistant to chemical and mechanical attack, ensuring greater durability and operational safety.

Main Advantages of Ebonite Lining

- High corrosion resistance

Ebonite withstands strong acids, saline solutions, and highly reactive compounds, protecting the metal against accelerated degradation. - Excellent mechanical resistance

Even though it is rigid, ebonite is capable of withstanding vibrations, impact, and continuous stresses from the mixing process. - Electrical insulation

In sensitive processes, the material's natural insulation increases operational safety. - Increased equipment lifespan

The protection reduces wear and minimizes maintenance costs. - Smooth internal surface

The finish improves fluid flow and prevents residue adherence.

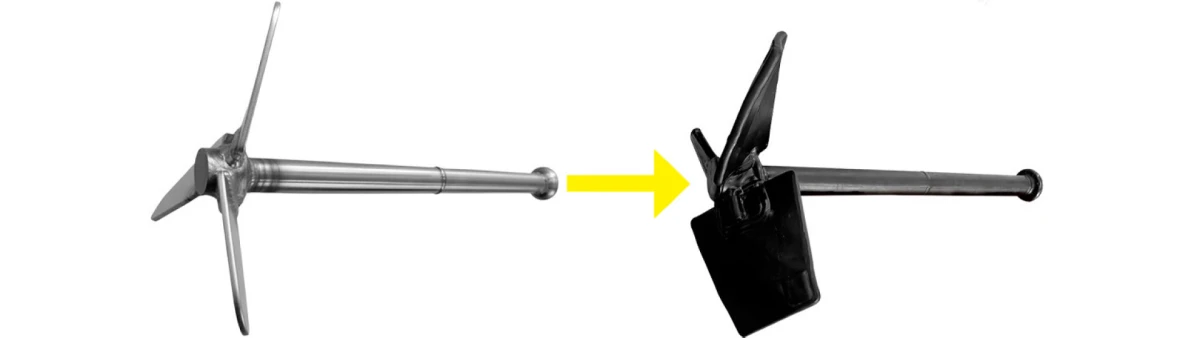

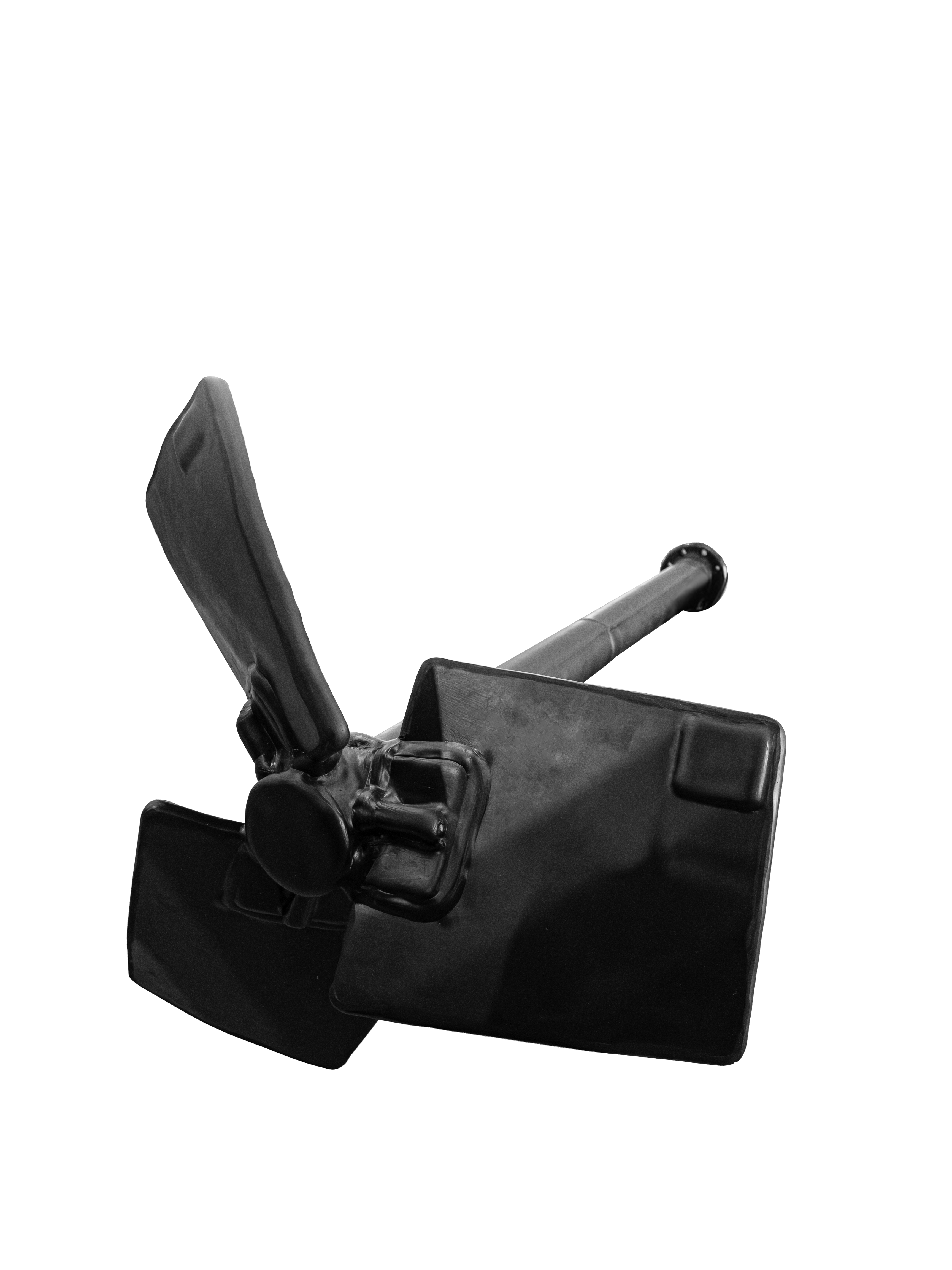

Agimix Project:

Agitator Coated in Ebonite

Agimix's most recent project was the development of an industrial agitator with complete ebonite lining. The objective was to meet a highly corrosive chemical process where conventional metallic components would be quickly damaged.

Project Highlights

- Application of a uniform layer of ebonite on all critical surfaces

- Controlled curing process to ensure perfect adhesion to the metal

- Mechanical and chemical tests before delivery

- Significant reduction of contamination and wear

- Expressive increase in the durability of the agitation assembly

The final equipment is capable of operating continuously in an aggressive environment with high reliability and low maintenance requirements.

Where Ebonite Lining is Most Used

The use of ebonite in industrial agitators is common in the following sectors:

- Chemical

- Water and effluent treatment

- Mining

- Pharmaceutical

- Pulp and paper

- Food and beverage

- Electroplating

These segments deal with corrosive, abrasive, or highly reactive fluids, situations where the lining makes a total difference.

When to Consider Using Ebonite

Ebonite lining is indicated when the process contains:

- strong acids or fluids with very low pH

- abrasive compounds

- high chance of accelerated corrosion

- need to reduce metal contamination

- requirement for longer equipment lifespan

- processes that require electrical insulation

If any of these conditions are part of your production scenario, ebonite may be the ideal solution.

Conclusion

Ebonite lining is a robust solution for those seeking superior performance, maintenance savings, and operational safety. The Agimix project demonstrates how choosing the correct lining can transform the resistance and efficiency of an industrial agitator.